Pressure Calibration

X2•Series instrumentation have thermally compensated pressure sensors. Each pressure sensor is calibrated in a temperature controlled bath at 12 C. The calibration points collected have three values associated with each point:

- The actual pressure applied by the dead weight tester

- The pressure sensor temperature compensation measurement (Npt)

- The pressure measurement (Np).

All this data is utilized in a three dimensional curve fit to generate the calibration coefficients.

The pressure sensor temperature compensation measurement is performed at the Wheatstone bridge of the pressure sensor. This helps to avoid thermal lag, which results in data spiking in high speed applications.

Older non-temperature compensated instruments are calibrated at room temperature using a dead weight tester. Ten to twelve pressure points are taken spanning the full scale range of the pressure sensor. The raw data from the pressure sensor measurement is then curve fit to the actual pressure applied by the dead weight tester.

Pressure Calibration Equations

AML Oceanographic utilizes three equations for calibrating piezoresistive pressure sensors. The choice of equation is instrument model specific.

In current sensor P•Xchange, used on X•Series instrumentation, temperature is internally compensated. Therefore, the same equation is used as that which is applied on older, non-temperature compensated instruments such as the CTD Plus and SV Plus:

P (dBar) = A+B*Np+C*Np2+D*Np3

Where A, B, C and D are calibration coefficients, and Np is the raw pressure sensor measurement.

There are two equations used for pressure calibrations where temperature is compensated externally. The first equation is used on a wide variety of instruments, including all pre-X•Series Micro instrumentation, SV Plus V2, and CTD Plus V2. The pressure calibration equation for these instruments is:

P (dBar) = A+B*Nc+C*Nc2+D*Nc3+(E+F*Nc+G*Nc2+H*Nc3)*Np+ I +J*Nc+K*Nc2+L*Nc3)*Np2

Where A through M are calibration coefficients, Nc is the thermal compensation number (Nc=Npt-M), Npt is the raw pressure sensor thermal compensation measurement, and Np is the raw pressure sensor measurement.

The second equation was used on a small number of early SV Plus V2 instruments. It uses the form:

P (dBar) = A+B*Npt+C*Npt2+D*Npt3+(E+F*Npt+G*Npt2+H*Npt3)*Np+(I+J*Npt+K*Npt2+L*Npt3)*Np2

Where A through L are calibration coefficients, Npt is the raw pressure sensor thermal compensation measurement, and Np is the raw pressure sensor measurement.

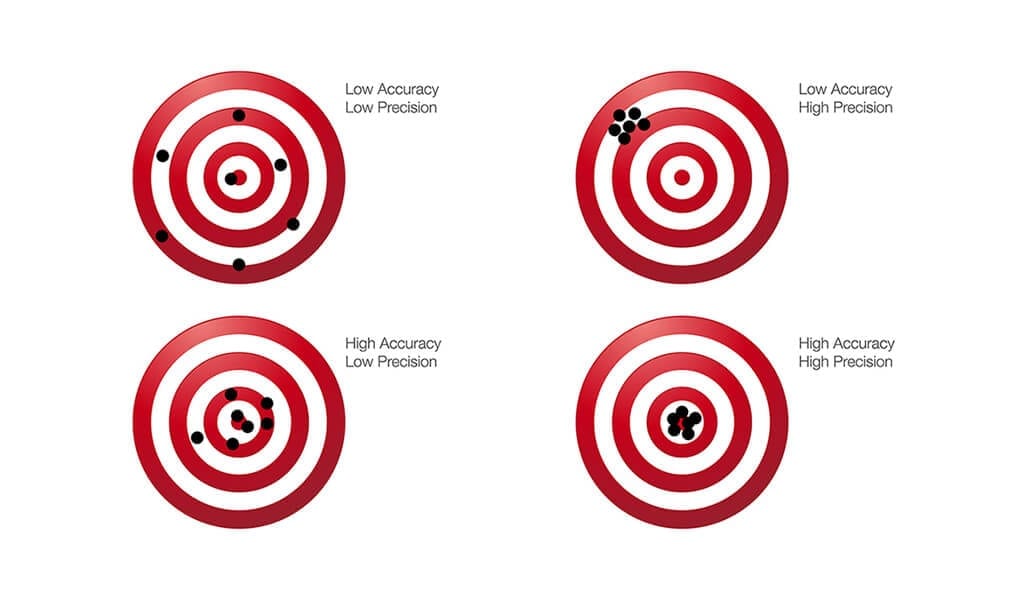

What is the difference between precision and accuracy?

Many vendors of oceanographic instrumentation refer to accuracy and precision interchangeably. They are not interchangeable. In effect, accuracy refers to how well a sensor performs against a known third party standard. For example, a temperature sensor may be +/- 0.001 C, as compared to a Black Stack themistor module. Precision refers to the repeatability of the readings of a given sensor. A sensor is precise when it repeatedly provides the same reading, regardless of how accurate that reading is.

A good analogy is a dart board. The thrower of darts is accurate when he or she is able to reach the target, the bulls-eye. He or she is precise if, having thrown three darts, all three land in the same location, irrespective of whether or not that location is the bulls-eye.

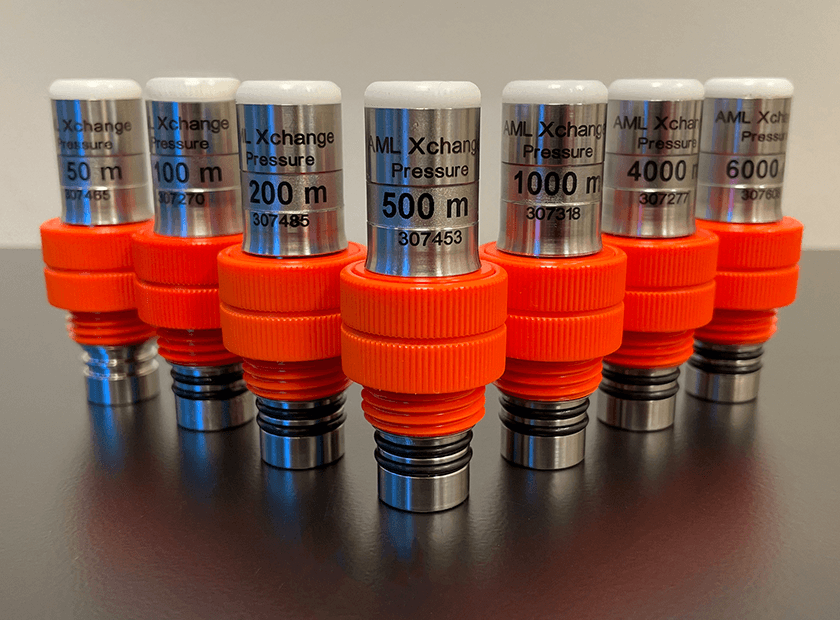

How often should I recalibrate my pressure sensors?

Like many other oceanographic sensors, there is no definitive answer. In general, the greater the number of pressure cycles, the more likely that a pressure offset will begin to occur. The likelihood of such an offset increases with a prolonged exposure to the upper pressure range of a sensor’s calibrated range (for example: a pressure sensor with a range of 0-100 dBar deployed on a platform situated at a depth of 100m for a long term in-situ application).

A deformation in the diaphragm of the pressure sensor is also likely to impact the calibration of that sensor. Such a deformation can occur if the sensor is poked with sharp objects (shown at left). A pressure sensor should always be returned for recalibration if it suffers such a poke or prod.

What is the difference between calibration range and survival depth?

The calibrated range of a pressure sensor is the normal operating range of the sensor where the pressure readings will fall within the sensor’s stated accuracy limits.

Pressure sensors can be over-ranged by 50% without causing damage to the sensor. In such a case, the sample points that lie beyond the calibrated pressure range of the instrument may not fall within the accuracy specifications of the instrument. However, the sensor will not suffer irreparable damage.

Burst pressure is that pressure at which irreparable damage is done to the sensor. In such a case, the sensor will flood and must be replaced. Burst pressure is normally 75% more than the stated pressure range on the sensor. If the instrument shares the depth rating of the installed pressure sensor, it too will flood upon reaching this burst pressure level. If a Pressure X2change of a certain range is installed on X2•Series instrument with a greater depth rating, and the instrument is deployed beyond the survival depth of the Pressure X2change but not that of the X2•Series instrument, only the Pressure X2change will be irreparably damaged.