Five Questions about Sensor Accuracy, Answered

By: Dustin Olender PhD, Director of Strategic Development - AML Oceanographic

Ever wonder what the numbers on sensor data sheets really mean, and how they are calculated? Read on!

Before you begin: AML prefers to use the International Vocabulary of Metrology (VIM, currently in the 3rd Edition), which covers a wide range of definitions used in metrology (the scientific study of measurement), such as trueness, precision, bias and drift. You’ll see these terms often in the explanations below, and blog posts by Dustin to come.

What is the definition of accuracy?

Is there a standard for accuracy?

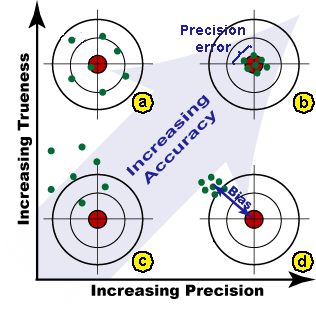

Figure 1: Bull’s-eye targets demonstrating the concept of trueness and precision. Here replicate measurements are green dots and the reference standard is the large red dot (or Bull’s-eye).

Precision is the closeness of agreement between replicate measurements. Analogous to accuracy it’s expressed numerically as “imprecision”. Precision error is calculated using the statistic of standard deviation (more on this in Q#3).

Trueness is the closeness of agreement of the average of many replicate measurements relative to a reference standard. Expressed numerically as an “intrueness”, that average error is known as bias.

Why would you want to discuss error this way? One explanation starts by looking at the various sources of error and their characteristics.

Ever hear that hissing sound in the background when listening to music? You may be listening to something called “thermal noise”, which is a random fluctuation of electrons, measured as voltage, in all electronic circuits. It sometimes gets amplified along with the audio signal. The circuits within marine sensors can require significant amplification, being even more sensitive to thermal noise. This is a good example of a precision error in a sensor.

Listen to thermal noise here.

Biofouling causes conductivity sensors to read lower than they otherwise would.

Conductivity sensors use glass tubes as part of their sensing elements. If seagrasses or other sea creatures are allowed to grow on the glass during deployments in tropical waters, the sensors read lower than they otherwise would[1]. The error increases as fouling increases. This error is referred to as “systematic”, because it affects all measurements similarly – forcing them low. It’s a good example of the bias that can develop in a sensor.

[1]Remember to use our UV anti-fouling technology for long deployments and this won’t be an issue!

IN OTHER WORDS

Imagine that your new puppy has ripped open a pillow while you were out of the room. You pick it up, and the feathers flow out. If the air is still, the feathers will land randomly around your feet. This is precision error. If you have a window open, however, and there is a slight breeze blowing in the direction of your kitchen, the feathers will all land off to one side. Due to the breeze, the feathers’ landing spots are biased towards a certain area. This is bias.

How do you quantify precision error? Or what standard deviation (SD) or RMS error?

If you look at the replicate measurements (green dots) near the bull’s eye at the bottom of Figure 2, you can see they’re grouped around a mean. It’s straightforward to calculate the mean (and the bias), but how would you calculate the precision error due to the random fluctuation around the mean?

The most common way to quantify precision error is to calculate the average distance of all these measurements from the mean. The field of Statistics does so in a particular way, calculating the square root of the average of squared errors, or root mean square (RMS) error. This is also known as the standard deviation (SD), and is sometimes symbolized as σ.

If you were to make many replicate measurements and stack those with similar size errors, you would eventually see the graph at the top of Figure 2. From this one can conclude that the chance or probability of a measurement being close to the mean is high, falling off the farther you get from it.

Figure 2: Dispersion of replicate measurements associated with precision. Note: only 3 stacks were shown for clarity.

Practically this means that 1 SD (1σ) tells us the error will be within that distance of the mean, 68% of the time – or the vast majority of the measurements. The value of an SD is often prefixed by ±, to indicate that it is a “half-width”, and the error could be either positive or negative. For a 95% probability, one can multiply the SD by 2. For a 99.7% probability, one can multiply the SD by 3, and so on. AML follows the field of Statistics, preferring the RMS error and reporting 1σ.

What is initial accuracy?

Learn how AML can make a difference for you.

X2change™ is the industry’s leading family of field-swappable sensor heads. Each sensor head contains its own embedded calibration and can be moved from instrument to instrument without impacting accuracy. Changing sensors is easy: simply unscrew one sensor head and replace it with another.