Modularity for All

From One Project to the Next

By: James Walton, Solutions Engineer & Dallace Johnson, Digital Marketing Lead - AML Oceanographic

Approximately 14 years ago, AML released the first-ever removable time-of-flight sound velocity sensor. It was around this time that AML started to play with the concept of modularity. The idea was simple. Why send the whole instrument back for service when users only want the SV sensor calibrated? One by one, AML’s sensors turned into “Lego” to make it easier to return sensors for calibration. The concept was popular, and AML started receiving small boxes containing sensors. Sensors from a dozen or more instruments would come back in a transit case no bigger than a briefcase. If the sensors weren’t modular, receiving them would have required a forklift.

It’s not hard to understand why this concept is attractive. If an asset has many functions, the utilization factor goes way up, and carrying costs go way down. No need to buy one of everything when one thing can do anything. Sorry, every equipment manager out there, that warehouse full of specialized single-purpose (idle) equipment isn’t very impressive. Adaptable gear is a worthwhile investment. It makes sense to pluck equipment from common stock, configure for the task at hand, and get to work.

Happenings Near And Far

AML may have ventured into the modular game early on, but nowadays savvy organizations and manufacturers are incorporating modularity into their core business. MEOPAR’s Modular Ocean Research Infrastructure (MORI) and Global Ocean’s Modular Adaptive Research Vessel (MARV) are programs built around the idea that ship time and personnel are the critical components. Their gear has to be adaptable to meet individual project needs. Manufacturers like Seaber and SAAB have also designed multi-purpose vehicles, such as the YUCO mini AUV and Double Eagle SAROV, with adaptability in mind.

Seaber's YUCO-PHYSICO micro AUV with AML-3 RT.

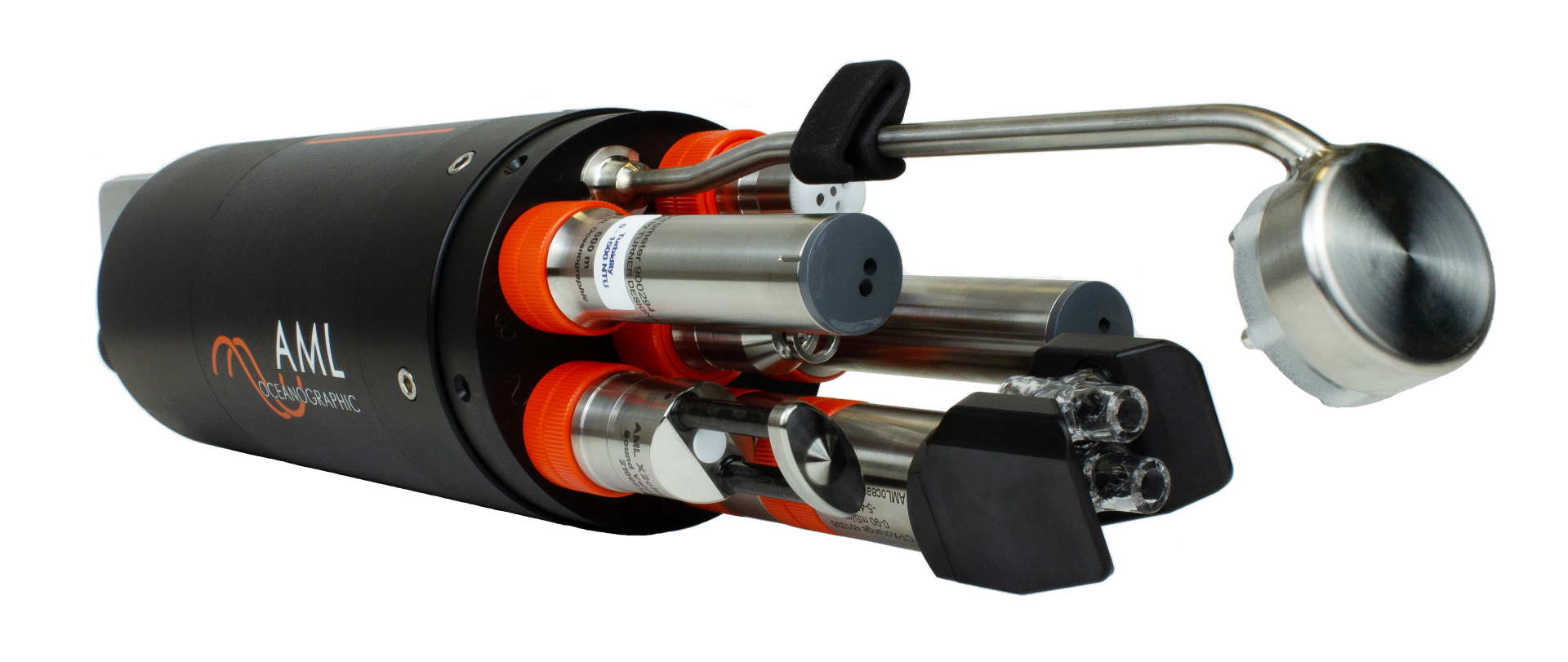

In 2020, AML Oceanographic debuted its second iteration of this modular technology with the X2•Series Instrumentation and X2change™ sensors. This generation seamlessly expands its offering beyond basic hydrography to include over twenty different parameters to suit a broad range of applications. The modular concept also got a lot more useful. Want to put any sensors anywhere? We’ve got you covered! Want multiples of the same parameter on one instrument? Why not, you’re the boss! Long gone are the days when an AML instrument was only considered for one job, one application.

AML-6 (without a cage) showing a possible sensor configuration.

Why Choose A Modular Solution?

When considering CTDs, SVPs, and multiparameter sondes, choosing a modular solution can unlock several advantages. For starters, it’s easier to train users on one type of instrument, one software, and one data QC process. Trying to memorize a bunch of procedures from various manufacturers gets too complicated. Once the user base is confident, there is no need for a large safety stock of replacements. One equipment pool supports many projects. When one sensor is inaccessible (due to calibration or repair), borrow a spare from another project. Additionally, organizations that embrace the modular approach will realize more efficient cash use. Preserve CAPEX through the reuse of equipment. Predict OPEX with standardized calibration and maintenance plans. Both save money for the company overall.

Custom configured AML-6 instruments with 7 sensors

AML’s sensor lineup, X2Change™, covers more applications than any other CTD manufacturer. Do you spend part of your time surveying with an ROV and another part casting by hand? Are you often working in shallow water but sometimes need to go deeper? Are you collaborating with colleagues who need datasets with different parameters? Do your clients demand higher accuracy sensors on a project-by-project basis? Do you battle with biofouling on long-duration data collection projects? If X2Change™ is your platform, you can realize all these and more.

Let’s get specific. The best example in the case for modularity is the AML-6 LGR with an extra wet mateable connector for real-time communication. It supports the combination of any six sensors, plus two extra via auxiliary inputs. To prevent biofouling, pop in the Streetlamp UV as needed. This industry-leading antifouling solution has its own port, so as not to replace a sensor. Ultraviolet lights shoot invisible death rays on any biofilm unlucky enough to set up base camp on sensor surfaces. Data are available in a few different ways such as WiFi download, USB access, or in real-time via the serial port. Output displays in a simplified column format or machine readable self-describing AML-x format. This instrument may sound like a beast, but it comes in at a modest 10 cm diameter by 60 cm long and weighs 4 kg. An instrument of this size is easy to deploy by hand and will fit all but the smallest vehicles. Equipment managers will appreciate the ability to plug and play according to project specs.

AML-6 end cap showing sensor and UV ports.

In Conclusion

The future is ripe with possibilities for modular instruments, systems, and methodologies. By going modular, users are able to think beyond current projects. Since the equipment is transferable between projects, CAPEX expenses decrease, saving the company money. Collaboration is key for the next generation of intuitive and practical devices. AML continues to work with organizations and fellow manufacturers to design innovative solutions.