5 Ways to Prepare Your MVP for Survey Season

By: Darrell Groom, Sales Engineer & Dallace Johnson, Digital Marketing Lead - AML Oceanographic

Survey season is coming, and it’s time to start dusting off your equipment. Below are five ways to prepare your MVP (Moving Vessel Profiler) for survey season.

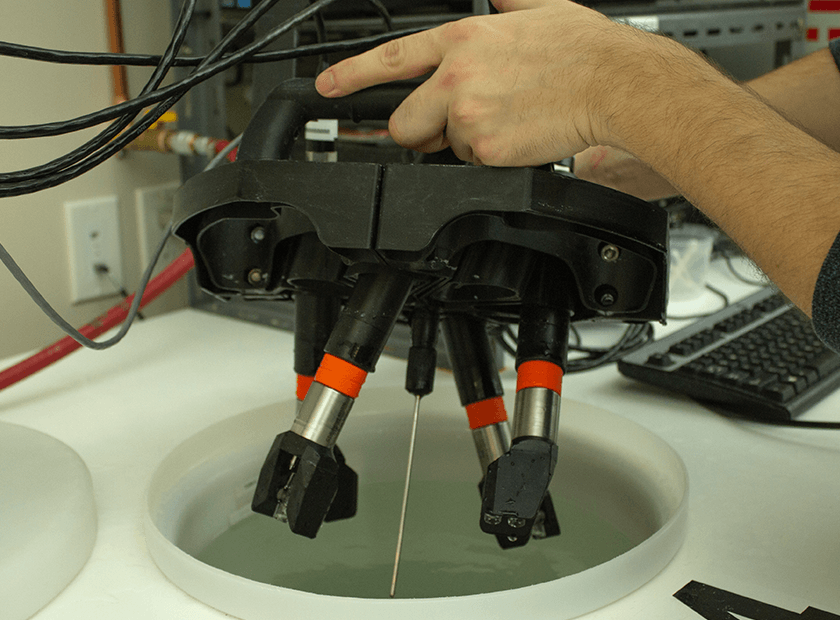

1. Got Calibrated Sensors?

The first thing to ask yourself is “When was the last time these sensors got calibrated?” If the answer is over a year ago (or a shoulder shrug), send your sensors back for a little TLC. To maintain accuracy, AML Oceanographic recommends you calibrate your sensors every year.

2. Check Yourself Before You Wreck Yourself

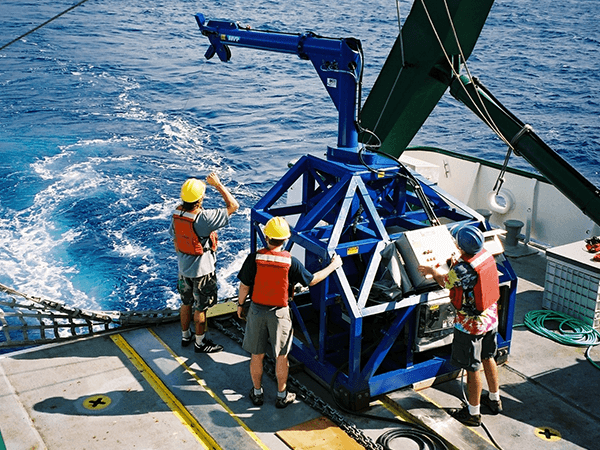

AML builds Moving Vessel Profilers to last - for over 15 years in some cases! That doesn’t mean it won’t show signs of wear and tear. Carry out a visual inspection of all structural components on the MVP to detect any deformities. Look for evidence of moisture inside the electrical control box and power box at the winch. Check the door seals for any signs of damage or corrosion. If either is present, remedy it as early as possible before the survey season starts.

Also check crucial components, like the tow cable. Inspect the condition of the mechanical and electrical termination for signs of damage. Note that the mechanical termination on the tow cable should be re-done yearly or every 2000 cycles. Also examine the tow body, instrument mounting assemblies, fasteners, and status of interconnect cables.

3. Wash & Lube

Wash down the tow body and instrument(s) with fresh water after storing them for an extended period. This will remove any salt residue and/or crystallization and prevent corrosion. Unless you like the shabby-chic rust aesthetic.

Grease any outer sheave pillow block bearings with EP-2 grease or equal. Your ears will thank you. Additionally, disconnect and inspect all electrical cables. Apply dielectric grease to the threads and pins before reassembling them. This prevents friction and adds to the longevity of your connectors.

WHAT EP-2 GREASE?

It is a general purpose lithium-soap thickened grease for extreme pressures. EP-2 grease is best used for applications that involve a wide range of temperatures and high/extreme pressure conditions.

4. Power It Up!

Nobody has to tell you how annoying it would be to go out in the ocean and have a critical piece of kit malfunction. Power up the MVP system and test all HAND mode functions. Make sure to rotate the drum in and out several times to test the ease of drum rotation and brake operation.

And finally (but perhaps most importantly)...

5. Location, Location, Location

Where you install your MVP is critical to its performance and maintenance needs. While the MVP is built for mission-critical applications, make sure of the following:

- Install the system in a location where it won't get submerged and/or take direct impact from waves. While the occasional blast is OK, pick a location that minimizes this risk. Spray and rain are fine... submersion is not!

- Plan for easy access to deployment and continuous operation. Check the MVP training manual for bend radius specifications. Besides adhering to this radius, limit the angular strain on the cable as much as possible.

- Ensure the cable run is secure and power is clean for the single or multi-phase AC power.